The company EUROFROST undertakes entirely the study, design, construction and maintenance of cooling chambers of preservation - freezing - deep freezing of food and air-conditioned places, where products and their processing require specific temperatures.

The wide range of leading and innovative products which is offered by our company can help you innovate and reduce your operating costs.

The wide range of leading and innovative products which is offered by our company can help you innovate and reduce your operating costs.

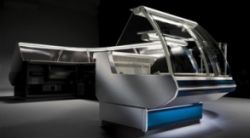

Besides, our company builds freezers of all types and sizes and equips butcher shops, super markets, mini markets, grill, coffee bars, hotels, foodservice, food etc.

Innovation

Our company provides to all of our installations the complete control of the operation of the cooling chambers. It also provides the ability to monitor all the refrigerators and the machinery by sending alarm via sms.

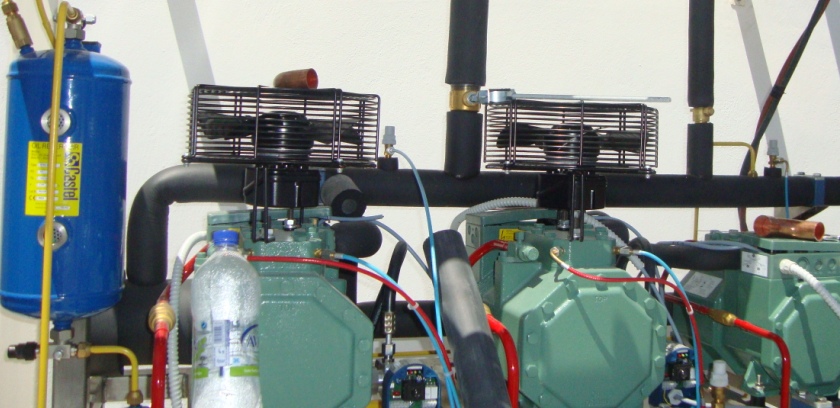

With the electronic management of the refrigeration units, we can achieve the maximum exploitation of the cooling capacity, so that we can achieve energy saving up to 33 %. Furthermore, the system stores temperature recorders, and it sends an sms when a function is outside the limits that we have set, so we can ensure anytime the quality of all the refrigeration products. We therefore suggest the installation of compressors in parallel network, with capacity control from the central controller with a common condenser. Electronic expansion valves are able to give us valuable information when necessary, for the operation of the cooling circuit. Also, the system adapts itself to better operation when required, by using the measurements of temperature sensors, and of pressure and overheating, thereby ensuring the proper freezing of the products, and energy saving. Million of tons of CO2 emissions could be avoided each year, if the electronic management system was installed in all food management facilities.

The monitoring program stores record temperatures for the food storage, which is needed by the health service.

The Temperature Recording and Alarm gives you the following options:

Create your own network of refrigerators or freezers

Monitor all your refrigerators through a central computer 365 days a year

Do the management, control and optimization in all parts of the cooling system, through integrated electronic controls that regulate the machines

Maximize the system efficiency

Reduce the maintenance costs

Increase the quality of food

Reduce the emission of CO2 into the atmosphere

Keep temperatures records for food storage required by the Health department

Acquire HACCP certification

Our technicians will ensure you the best possible application of your equipment and the immediate ongoing support over time.

Our company in cooperation with the company AMERICAN MOTORS installs collapsible prefabricated cold rooms of insulating polyurethane panels which are easily assembled, with adjustable dimensions.

Our company in cooperation with the company AMERICAN MOTORS installs collapsible prefabricated cold rooms of insulating polyurethane panels which are easily assembled, with adjustable dimensions.

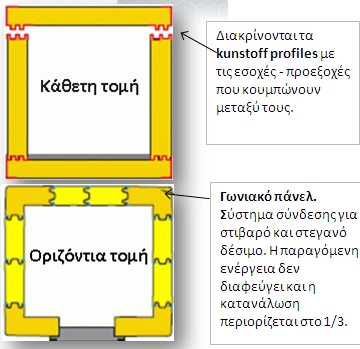

The factory produces many types of polyurethane panels for different uses. The panels for use in cold stores of polyurethane panels, stand out of the three (3) thermal barriers they have on their connection sides, to hold the generated energy (cooling) and as hohlkammerprofil (hall Kammer profile) (HRP), which is incorporated in panels in the form of longitudinal flange to seal airtight connections (internal-external) and cover the joints, eliminating the grooves according to EU directives.

The panels for the refrigerated chambers interlock tightly with snap-in system. Modern machinery guarantees the absolute accuracy in each chamber. Guarantee of the tightness of the cooling chamber is the quality control process, which is certified with CE 89/106 EN13241-1 in accordance with the European directive EN 89/106/EK.

The connections of the panels, in refrigerating chambers, are made with new technology and in accordance with the directive of the health services of the European Union (specifications HACCP), which prevents the joints between the panels, because there are collected salmonella bacteria, coliform bacteria, fungi, parasites, etc.

The panels are connected together with three thermal barriers to ' hold ' effective cooling, against the flat connections of competition, which are made exclusively for lining metal buildings, without the thermal insulation requirements for refrigerating chambers . They are lined with 3 white sheet steel, RAL 9002, thickness 0,55 mm, with antitoxic polyester coating NSF and protective FOIL.

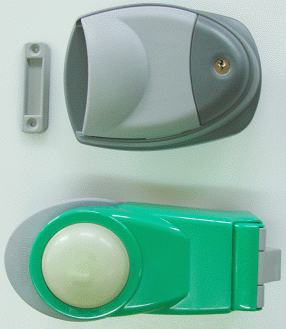

The door, as a key element of the structure and function of the cooling chamber fits perfectly, seals, and contributes significantly to maintain a constant temperature inside the chamber. Specifications :

- They are MONOBLOCK in all dimensions, ie a pouring polyurethane (a single panel). A key advantage to not deform.

- Invested with German steel sheets 0,65 mm thickness with lamination thickness of 200 microns .

- Select dimensions that fits you

- Sliding doors are manual or automatic electric

- Available in various colors